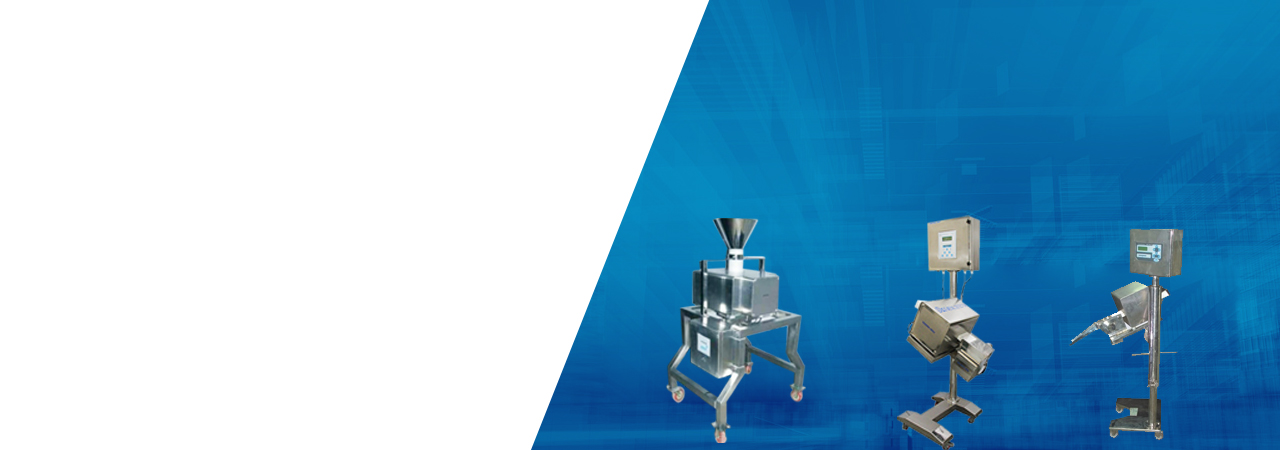

Tablet Deduster

300000.00 INR/Unit

Product Details:

X

Tablet Deduster Price and Quantity

- 1 Unit

- 300000.00 INR/Unit

Tablet Deduster Trade Information

- Mumbai

- 30 Unit Per Month

- 4 Week

- As per Requirement

- Chandigarh Himachal Pradesh Andaman and Nicobar Islands Dadra and Nagar Haveli South India North India East India West India Assam Arunachal Pradesh Bihar Chhattisgarh Delhi Gujarat Goa Haryana Daman and Diu Jammu and Kashmir Jharkhand Karnataka Kerala Lakshadweep Madhya Pradesh Maharashtra Mizoram Meghalaya Manipur Nagaland Odisha Punjab Pondicherry Rajasthan Sikkim Tamil Nadu Telangana Tripura Uttar Pradesh Uttarakhand West Bengal Andhra Pradesh Central India All India

- ISO

Product Description

Our tablet deduster is designed for expulsion of over-abundance dust from squeezed tablets. It is a rapid machine that expels dust from squeezed pharmaceutical tablets. This is an exceptionally adaptable machine that can suit diverse yield speeds and the tallness is flexible to fit any kind of tablet press. Our tablet deduster expels over-abundance tidy from squeezed pharmaceutical tablets. The cleaning of tablet is accomplished through vibratory impact. Every contact segments are white delrin or stainless steel. The head is effortlessly evacuated as an entire unit with the discharge of two hooks. This permits for fast compatibility of the upper area when cleaning or when moving from item to item.

Characteristics of Tablet Deduster:

- Stainless steel dedusting structure with nonstop welded winding plate

- Spotless untainted steel stand along with sterile locking floor casters

- Brisk disassembling

- Contemporary plan to acknowledge diverse tower statures

- Movable to suit distinctive press outputs

- Window permits swings open and visual examining for tablet inspection

Tablet Dedusting Machine Specifications:

|

Grade |

SS304 |

|

Finish |

Matt |

Additional Information of Tablet Deduster:

|

Product Code |

19 |

|

Min. Order Quantity |

01 Piece(s) |

|

Port |

Mumbai |

|

Payment Terms |

Other |

|

Delivery Time |

4 weeks |

|

Packaging Details |

Standard |

Technical Specifications of Tablet Deduster:

|

Type NOF DE-DUSTER |

Elevating Type |

|

MOC |

SS 304 and Contact Parts Ss316 and Struture Will Ms Hard Chrome Plated. |

|

Output |

500000 Tablets / Hour of Size 11-12 Mm Diameter. |

|

Speed |

Variable |

|

Input Supply |

230 V/50Hz Ac Normaly and 110 Vac On Demond. |

|

Orientation |

Inbuit It Can Be Rotate 360 Degree. |

|

Height Adjustment Span |

200mm |

|

No. of Spiral |

4 Nos. |

|

Additional Features |

PU Wheel, Vacum Nosel and Heavy Duty 12 Vibrator |

|

Validation Document |

DQ/IQ/OQ/PQ Will Be Provided |

FAQs of Tablet Deduster:

Q1: What is the reason for a tablet deduster?

A1: The main role of a tablet deduster is to eliminate overabundance dust, fine particles, or surface flotsam and jetsam from drug tablets or pills after they have been compacted or covered. This works on the quality and presence of the tablets and guarantees that they fulfill administrative and quality guidelines.

Q2: How does a tablet deduster work?

A2: Tablet dedusters work by passing tablets on through a pivoting drum or a vibrating screen. As the tablets travel through the deduster, air is drawn through the screen or drum, making a pull impact. This pull eliminates free residue and particles from the tablet surfaces, and the gathered residue is normally gathered in a different holder or channel.

Q3: Are tablet dedusters simple to clean and keep up with?

A3: Tablet dedusters are intended to be moderately simple to clean and keep up with. Ordinary cleaning is fundamental to forestall cross-defilement and guarantee steady dedusting execution. Support prerequisites might change relying upon the particular deduster model.

Q4: Are tablet dedusters utilized in different enterprises other than drugs?

A4: While tablet dedusters are basically utilized in the drug business, comparable dedusting cycles might be utilized in different ventures where tidiness and item quality are fundamental. For instance, tablet dedusters or comparable hardware might be utilized in the nutraceutical or dietary enhancement industry.

Q5: Could tablet dedusters at any point deal with various tablet sizes and shapes?

A5: Numerous tablet dedusters are flexible and can deal with a scope of tablet sizes and shapes. They can be modified or adjusted to oblige explicit tablet aspects and creation prerequisites.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

|

DAS ELECTRONICS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |