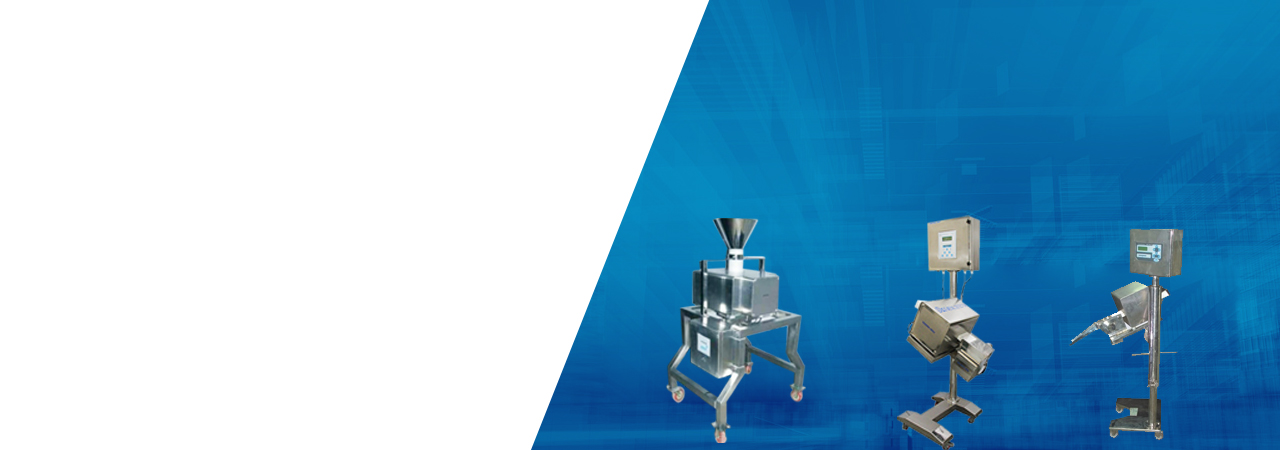

Milk Powder Metal Detector

300000 INR/Unit

Product Details:

- Power Supply Electric

- Alarm Led Lights,Sound

- Product Type Milk Powder Metal Detector

- Color Sliver

- Material Stainless Steel

- Click to View more

X

Milk Powder Metal Detector Price And Quantity

- 1 Unit

- 300000 INR/Unit

Milk Powder Metal Detector Product Specifications

- Stainless Steel

- Led Lights,Sound

- Milk Powder Metal Detector

- Sliver

- Electric

Milk Powder Metal Detector Trade Information

- Mumbai

- Cash on Delivery (COD) Letter of Credit at Sight (Sight L/C) Cash in Advance (CID) Cheque

- 100 Unit Per Month

- 4 Week

- As per requirement

- Western Europe Asia Australia North America Eastern Europe Middle East Central America South America Africa

- Dadra and Nagar Haveli Himachal Pradesh Andaman and Nicobar Islands Uttarakhand Daman and Diu Lakshadweep South India Central India East India Andhra Pradesh Assam Arunachal Pradesh Chandigarh Delhi Goa Nagaland Jammu and Kashmir Jharkhand Karnataka Kerala Maharashtra Mizoram Meghalaya Manipur Odisha Pondicherry Rajasthan Sikkim Tamil Nadu Tripura West Bengal All India Haryana Uttar Pradesh Gujarat Madhya Pradesh North India Punjab Bihar Telangana West India Chhattisgarh

Product Description

Our milk powder metal detector is accessible by the customers in both compact as well as standard versions, which are utilized in pipelines of gravity feed to check for non-required metal impurities in constant circulation of powders and granules like flour, spices, sugar and corn meat.

Product sensitive components are manufactured in compliance with FDA food class quality norms. As large quantity material circulation by our milk powder metal detector, eliminates folds fast separate even the tiniest piece of metal non-required materials from the circulation of products. Handling free outline and fantastic development guarantee dependable working in the most difficult industrial conditions.

Advantages and Properties:

Product sensitive components are manufactured in compliance with FDA food class quality norms. As large quantity material circulation by our milk powder metal detector, eliminates folds fast separate even the tiniest piece of metal non-required materials from the circulation of products. Handling free outline and fantastic development guarantee dependable working in the most difficult industrial conditions.

Advantages and Properties:

- Small outline: Our Detector brags the industry's most limited installation stature.

- A setting frame with included metal free area permits for outstandingly simple and fast installation

- A stone strong sensor mounting frame and head configuration guarantee steady unwavering quality and execution.

- Various reject alternatives: Our milk powder metal detector comes with tidy fixing is suggested for powders. It is most appropriate for usages with quick circulating products. Further, the dismiss system is made to tolerate the difficulties of corrosive products as well as to not wear out.

- Product effect compensation

- Audio and visual indication on metal detection

- Very high sensitivity

- IP 65 control panels

- Stainless steel 304

- Model AMD (All Metal Detection)-Detects Ferrous, Non-Ferrous and stainless steel

- Model-FMD (Ferrous Metal Detection)-Detects Ferrous metal in metallised (aluminum) film packaging

- Model-FAMD-combination of above two (AMD+FMD) model

- Pneumatic flap, Air jet types of reject mechanism as per applications

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Food Metal Detectors' category

|

DAS ELECTRONICS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |