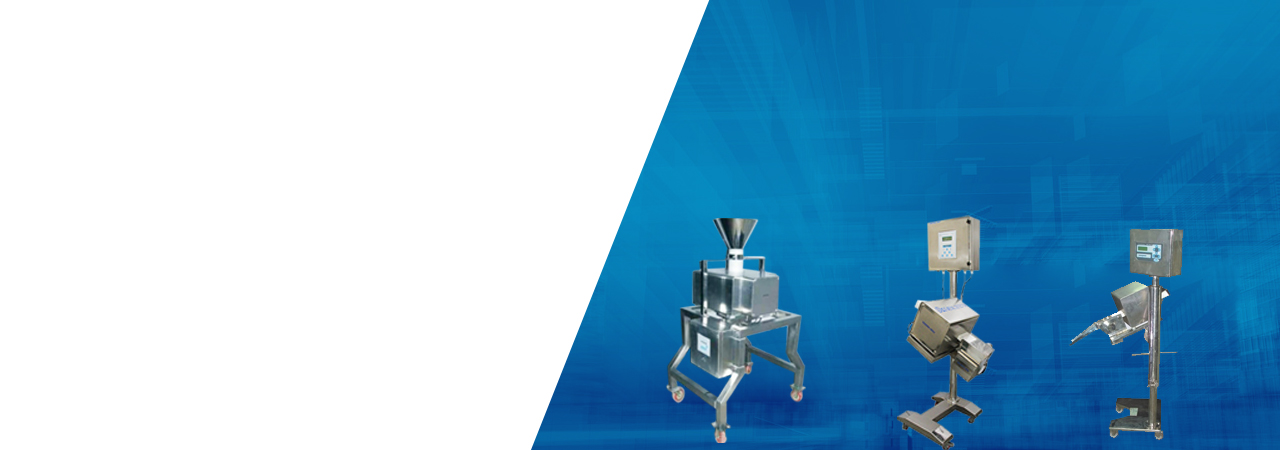

Stainless Steel Food Metal Detector

300000 INR/Unit

Product Details:

- Product Type Food Metal Detector

- Material Stainless Steel

- Alarm Led Lights,Sound

- Power Supply Electric

- Click to View more

X

Stainless Steel Food Metal Detector Price and Quantity

- 300000 INR/Unit

- 1 Unit

Stainless Steel Food Metal Detector Specification

- Led Lights,Sound

- Stainless Steel

- Food Metal Detector

- Electric

Stainless Steel Food Metal Detector Trade Information

- mumbai

- Cash Advance (CA) Letter of Credit at Sight (Sight L/C) Cash in Advance (CID) Cheque

- 100 Unit Per Month

- 4 Week

- Contact us for information regarding our sample policy

- logistic or transport charges as per availability.

- Australia South America Eastern Europe Western Europe Middle East Central America Africa Asia North America

- Chandigarh Himachal Pradesh Andaman and Nicobar Islands Pondicherry Uttarakhand Daman and Diu Dadra and Nagar Haveli Lakshadweep East India Assam Punjab Meghalaya Tamil Nadu Tripura Jammu and Kashmir West India Jharkhand Karnataka South India Goa West Bengal Nagaland Manipur Arunachal Pradesh Andhra Pradesh Sikkim Maharashtra Mizoram Rajasthan Haryana Delhi Gujarat Uttar Pradesh Madhya Pradesh North India Bihar Telangana Kerala Central India Odisha Chhattisgarh All India

Product Description

To create your products safe, to provide protection to your instruments and to fulfill administrative demands, our company is involved in providing stainless steel food metal detector to all parts of the sustenance preparing businesses. Our tunnel, surface or conveyor identifiers are by a wide margin the most well-known type of metal identification in the sustenance preparing industry. It can distinguish metal materials in a broad array of products in a conveyor line from packed cheddar products, to frosty meat, beverages, baked products, unprocessed products, vegetables and fruits.

Our stainless steel food metal detector is exclusively designed by us, this is an extraordinary metal detection advancement that both improves sensitivity to every metal impurities and decreases product impact in an extensive range of feasible products.

By perceiving the diverse frequency reaction of conductive metals and products, this technology drops item impact and keeps up superior levels of execution for every sort of metal stuffs, both non-magnetic and magnetic.

Stainless Steel Food Metal Detector Features:

- Design of our range is in compliance with HACCP standards

- Assurance from water and dust

- Simple operation, with a large color touch display

- Programmed affectability function

- Variable belt speed

- Hygienic outline as well as reasonable for working in a wet environ

- Examination record function recording various checking results

- Direct cleaning and easy handling with a separable conveyor line

Additional Information of Stainless Steel Food Metal Detector:

|

Min. Order Quantity |

01 Piece(s) |

|

Port |

Mumbai |

|

Payment Terms |

Other |

|

Delivery Time |

4 weeks |

FAQs of Stainless Steel Food Metal Detector:

Q1: What is the reason for a stainless steel food metal detector?

A1: The main role of a stainless steel food metal detector is to improve the security and quality control of food items, particularly those that come into contact with stainless steel gear or bundling, by distinguishing and eliminating metallic pollutants or unfamiliar articles that might be available during handling or bundling.

Q2: How does a stainless steel food metal detector work?

A2: Stainless steel food metal detectors work on similar standards as other metal detectors in the food business. They radiate an electromagnetic field and examine the signs got from food items as they go through the field. On the off chance that a metal pollutant is available, it upsets the field, setting off a caution and a dismissal instrument to eliminate the tainted food from the creation line.

Q3: What kinds of metallic pollutants might these detectors at any point distinguish in food items?

A3: Stainless steel food metal detectors are intended to identify a great many metallic impurities, including ferrous metals (iron and steel), non-ferrous metals (copper, aluminum, and so on), and stainless steel. They are delicate to both attractive and non-attractive metals.

Q4: Could these detectors at any point separate between metal impurities and stainless steel gear or bundling materials?

A4: Present day stainless steel food metal detectors are intended to recognize metal impurities and stainless steel hardware or bundling materials. They utilize progressed programming and sign handling to limit phony problems brought about by stainless steel parts.

Q5: Could these detectors at any point deal with various sorts and sizes of food items?

A5: Indeed, stainless steel food metal detectors are flexible and can deal with an assortment of food item types, including strong foods, fluids, powders, from there, the sky is the limit. They can be changed in accordance with oblige different item sizes and shapes.

Q6: What happens when a metal foreign substance is distinguished by the machine during food handling?

A6: When a metal toxin is recognized, the stainless steel food metal detector normally sets off a caution and, by and large, enacts a dismissal system. This system eliminates the polluted food from the creation line, guaranteeing that it doesn't arrive at purchasers.

Enter Buying Requirement Details

Other Products in 'Food Metal Detectors' category

|

DAS ELECTRONICS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |