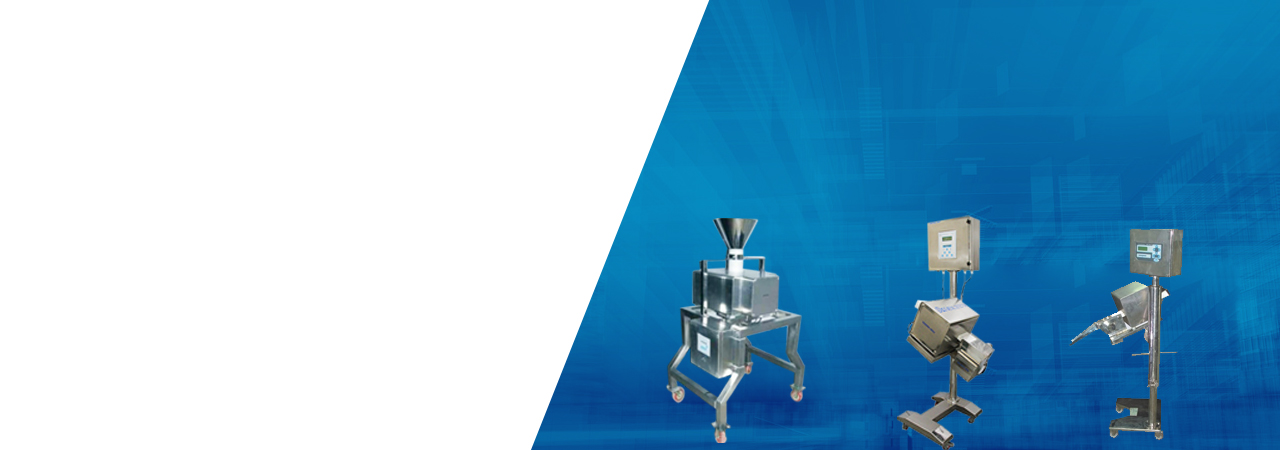

Gravity Feed Metal Detector

300000 INR/Unit

Product Details:

- Product Type Gravity Feed Metal Detector

- Power Supply Electric

- Alarm Sound

- Material Stainless Steel

- Click to View more

X

Gravity Feed Metal Detector Price and Quantity

- 300000 INR/Unit

- 1 Unit

Gravity Feed Metal Detector Specification

- Sound

- Gravity Feed Metal Detector

- Stainless Steel

- Electric

Gravity Feed Metal Detector Trade Information

- Mumbai

- Cash Advance (CA) Letter of Credit at Sight (Sight L/C) Cash in Advance (CID) Cheque

- 100 Unit Per Month

- 4 Week

- As per requirement

- Asia Australia North America South America Eastern Europe Western Europe Middle East Africa Central America

- Himachal Pradesh Andaman and Nicobar Islands Uttarakhand Daman and Diu Dadra and Nagar Haveli Lakshadweep South India East India Andhra Pradesh Assam Arunachal Pradesh Bihar Chandigarh Goa Jammu and Kashmir Madhya Pradesh Maharashtra Mizoram Meghalaya Manipur Punjab Pondicherry Rajasthan Sikkim Tamil Nadu Telangana Tripura West Bengal Jharkhand Nagaland Haryana Delhi Uttar Pradesh Gujarat Karnataka North India Kerala Central India Odisha West India Chhattisgarh All India

- ISO

Product Description

Being a client centric firm we offer heightened quality Gravity Feed Metal Detectors, and we feel immense pleasure to introduce ourselves as the leading manufacture, exporter and suppliers of top grade machinery. Our sophisticated system of working enable us to deliver products in the shortest possible lead time given by the client. creative designs, quality and timely delivery are the cornerstone of our organization. Here are some of the key focusing features of these particular products include these are made in maintenance free design, high quality construction and reliable operations, these features makes us the leading brand.

Our business offers Gravity Feed Metal Detector, which help with examining free circulating mass granular or powder materials such as flour, cereal, chemicals and so on. The array provided by us possess an inherent LED bar presentation to show the amount of tainting in the inspected product.

It is simple to work on as well as possess advanced plug in system of card. This metal detecting machine is broadly applauded because of high limit micro-regulator for accuracy and speed. Our gamut has been extraordinarily intended to meet the cleanliness norms of pharmaceutical and food industry. This guarantees that our customers products are of high caliber with no defilement and give most extreme fulfillment to customers. The uncommon nature of this Gravity Feed Metal Detector is that does it isolate ferrous as well as non-ferrous material and in addition stainless steel components as well.

Characteristics of Gravity Feed Metal Detector:

- Handling Free

- Propelled Dismiss Process

- Simple To Operate And Install

- Can Oversee High Workloads

- Simple To Keep Up And Clean Because Of Stainless Steel Structure

- High Ability Of Product Memories

- Programmed Parameter Retention

- Rejection And Detection Counters

Additional Information of Gravity Feed Metal Detector:

|

Product Code |

MD-011 |

|

Min. Order Quantity |

01 Piece(s) |

|

Port |

Mumbai |

|

Payment Terms |

Other |

|

Delivery Time |

4 weeks |

|

Packaging Details |

STANDARD |

FAQs of Gravity Feed Metal Detector:

Q1: What is a gravity feed metal detector?

A1: A gravity feed metal detector is a modern machine used to identify and eliminate metal impurities from quickly dropping mass materials, regularly in a granular or powdered structure. It's generally utilized in businesses, for example, food handling, drugs, and plastics.

Q2: How does a gravity feed metal detector work?

A2: Gravity feed metal detectors work in light of electromagnetic enlistment. The framework makes an attractive field inside the material's stream way. At the point when metal toxins go through this field, they upset it, setting off a caution and frequently a programmed dismissal system.

Q3: What sorts of materials can be investigated utilizing gravity feed metal detectors?

A3: Gravity feed metal detectors are reasonable for examining an extensive variety of mass materials, including grains, powders, granules, nuts, seeds, and other free materials. They are regularly utilized in the food business to guarantee item security.

Q4: For what reason are gravity feed metal detectors significant in the food handling industry?

A4: In the food business, gravity feed metal detectors are essential for quality control and security. They assist with forestalling metal impurities, like metal pieces or unfamiliar articles, from entering the eventual outcome, decreasing the gamble to purchasers and limiting item reviews.

Q5: Are gravity feed metal detectors delicate to various kinds of metals?

A5: Indeed, gravity feed metal detectors can be aligned to distinguish different sorts and sizes of metals, including ferrous (iron), non-ferrous (aluminum, copper, and so forth), and treated steel pollutants. They offer customizable responsiveness levels.

Enter Buying Requirement Details

Other Products in 'Metal Detectors' category

|

DAS ELECTRONICS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |